Name plates made from stainless steel offer excellent resistance to corrosion, chemicals, and staining, have high temperature resistance, and being a hard material, is resistant to abrasion. For both anodising and etching, Permark record and test each production batch to ensure consistent quality. For anodised plates, the anodic layer thickness for each batch is measured to be certain the process has resulted in a thick hardened layer for protection. Experience has shown that tight control of the parameters that create interaction between metal and chemicals to etch and anodise nameplates will result in repeatable and superior products. The name plates can be decorated on both sides if required.īecause the images and inks are recessed into the surface of the plate, they are less susceptible to damage from surface abrasion, and because the images have been etched into the plates, even if the inks were somehow scratched away, the etched impression is still visible.įurther decoration can include a clear sprayed protective coating (in particular for brass nameplates) lamination of protective film and the depositing of Resin onto the finished plates to form a domed resin nameplate is also possible.Ī fair amount of science goes into making metal nameplates. The plates are then baked to cure the inks. Specially formulated inks are then either screen printed or paint filled into the etched plates. Mounting holes ready for rivets or screws can be supplied in the plates, and/or specialty adhesive backing can be applied – which are selected to suit the material the plate will be adhered to.įor the most durable graphic images, Permark chemically etch images into the surface of the metal plate. This can be achieved in several ways, by printing or chemical etching, by diamond scratch engraving or laser engraving, or for serialised numbers, by sequentially stamping numbers onto the plates with a press.įor higher volume applications where variable information is added to nameplates, Permark can provide management of the plates by holding the manufactured “blanks” in stock, and adding the variable information on an order by order basis as required.

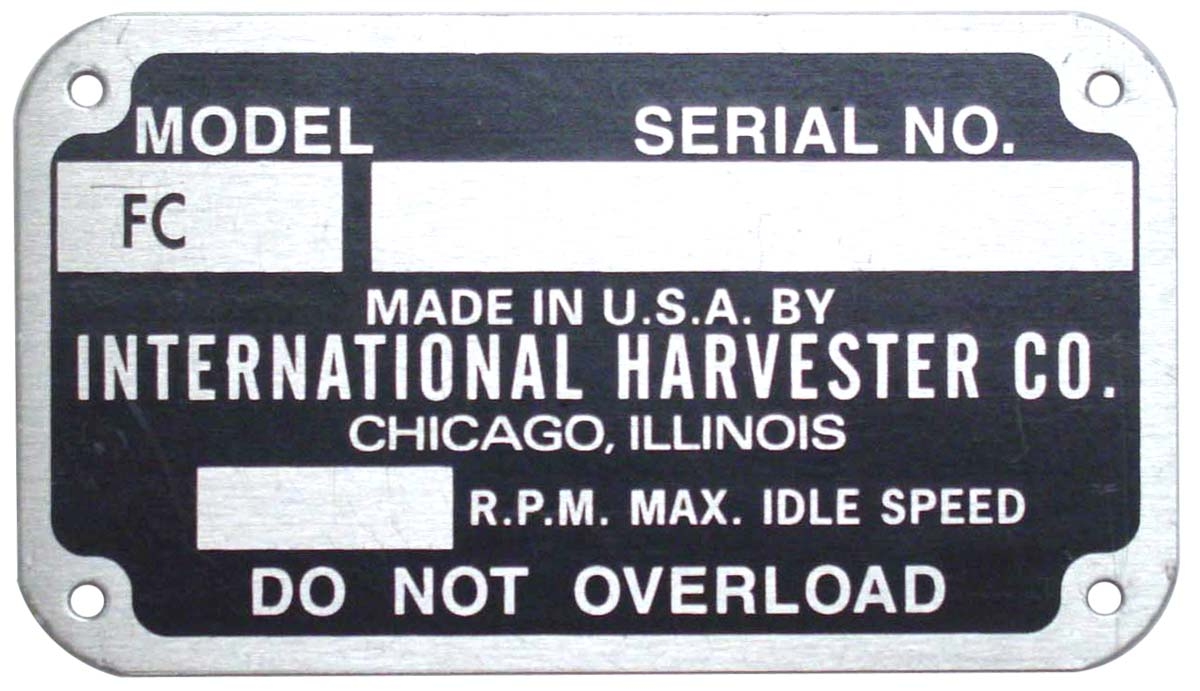

Many nameplates require unique or variable rating information to be printed onto the plates.

Material finish varies depending on the metal selection – visit the specific metal pages for Aluminium, Stainless Steel and Brass for further details. Material gauge depends on the application and such things as what mechanical strength the plate is required to have, the type of finish, and what environment the plate will be placed in. Permark’s metal name plates are most commonly made from Aluminium, Stainless Steel and Brass substrates, but also from tin plate and aluminium foil.

0 kommentar(er)

0 kommentar(er)